Coupling of conveyors with different velocities

- Problem:

- two coupled conveyors, lengths l1,2 and

constant velocities v1,2

- continuous process for connected conveyors

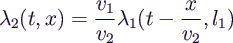

- → simply change line load λ2 by factor

v1/v2

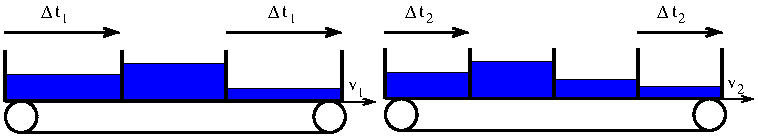

- discrete process with different lE1,2 and

∆t1,2

- conveyor 1 sends entities with time intervals ∆t1

- conveyor 2 outputs entities with time intervals

∆t2

- timing doesn't fit

- Basic idea:

- entity ≙ content of a given compartment on a conveyor

- created and filled at the entrance

- emptied and destroyed at the exit

- how to compute mass mout of a new entity

for conveyor 2?

- requirements

- mass conservation on short time scale

- homogeneity, i. e. output distribution similar to

input

- crucial parameter

- k > 1 → add up incoming masses to one

compartment

- k < 1 → distribute incoming mass to several

compartments

- simple case k∊ℕ → add up k incoming masses

- simple case 1/k∊ℕ → distribute incoming mass to 1/k

outgoing masses

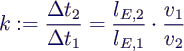

- Strategy for k > 1:

- introduce virtual bin with mass macc

between conveyors

- incoming entities fill bin

- outgoing entity empties bin

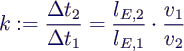

- example

- lE1 = lE2 = 1 m, v1

= 2.5 m/s, v2 = 1 m/s, min ≡ 1 kg

- → ∆t1 = 0.4 s, ∆t2 =

1 s, k = 2.5

-

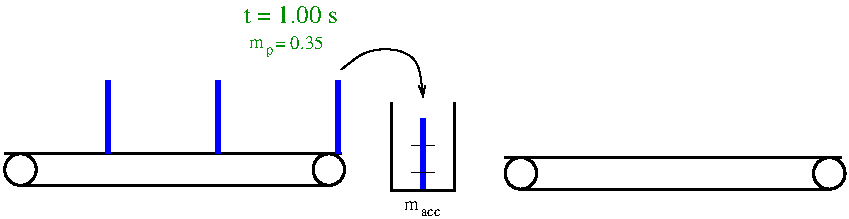

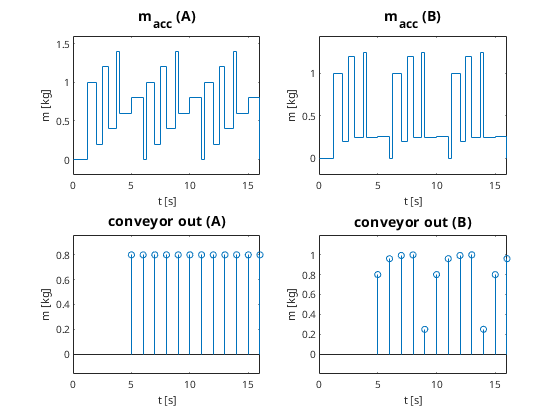

- Strategy A for k < 1:

- again virtual bin with mass macc between

conveyors

- each time min arrives: compute partition

mass mp

- mass of outgoing entity

- good example

- ∆t1 = 1 s, ∆t2 = 0.35 s → k

= 0.35

-

- very homogenous distribution

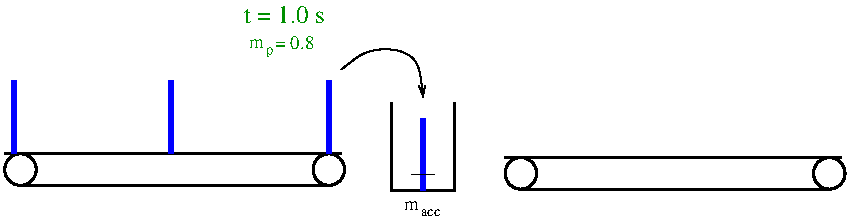

- bad example

- ∆t1 = 1 s, ∆t2 = 0.8 s → k

= 0.8

-

- macc grows → short time mass

conservation violated

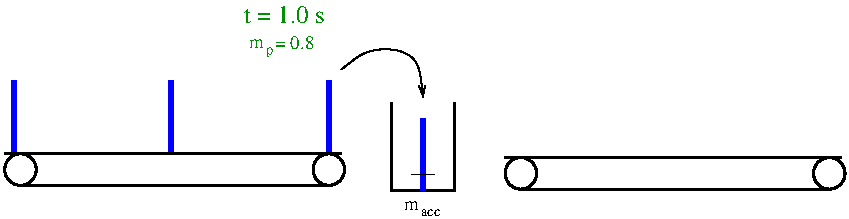

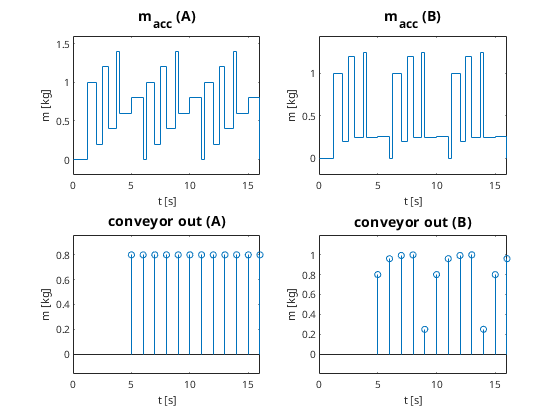

- Strategy B for k < 1:

- like A, but changed partition size

- mp = k macc

- distribute the surplus of macc

- precise mathematical description in paper

- bad example (k = 0.8)

- comparison

- B: much better short time mass conservation

- A: better homogeneity